Prime Minister Narendra Modi’s first official state visit to the United States brought forth significant opportunities for India’s semiconductor industry. During his visit, PM Modi extended invitations to prominent American chip makers, Micron Technology and Applied Materials, aiming to bolster semiconductor manufacturing in India. The move is part of the government’s ambitious Production-Linked Incentive (PLI) Scheme, which offers financial incentives to companies establishing semiconductor manufacturing plants in the country.

India currently imports all chips and the market is estimated to touch USD 100 billion by 2025 from USD 24 billion now. However, for the domestic manufacturing of semiconductor chips, India has recently launched several initiatives such as the allocation of Rs 76,000 crore by the Union Cabinet in 2021 for supporting the development of ‘semiconductors and display manufacturing ecosystem’.

the launching of scheme for Promotion of Manufacturing of Electronic Components and Semiconductors (SPECS) for manufacturing of electronics components and semiconductors, and the launch of Design Linked Incentive (DLI) Scheme by MeitY to nurture at least 20 domestic companies involved in semiconductor design and facilitate them to achieve a turnover of more than Rs.1500 Crore in the next 5 years.

Significance of the deal:

- Expanding India’s Semiconductor Manufacturing:

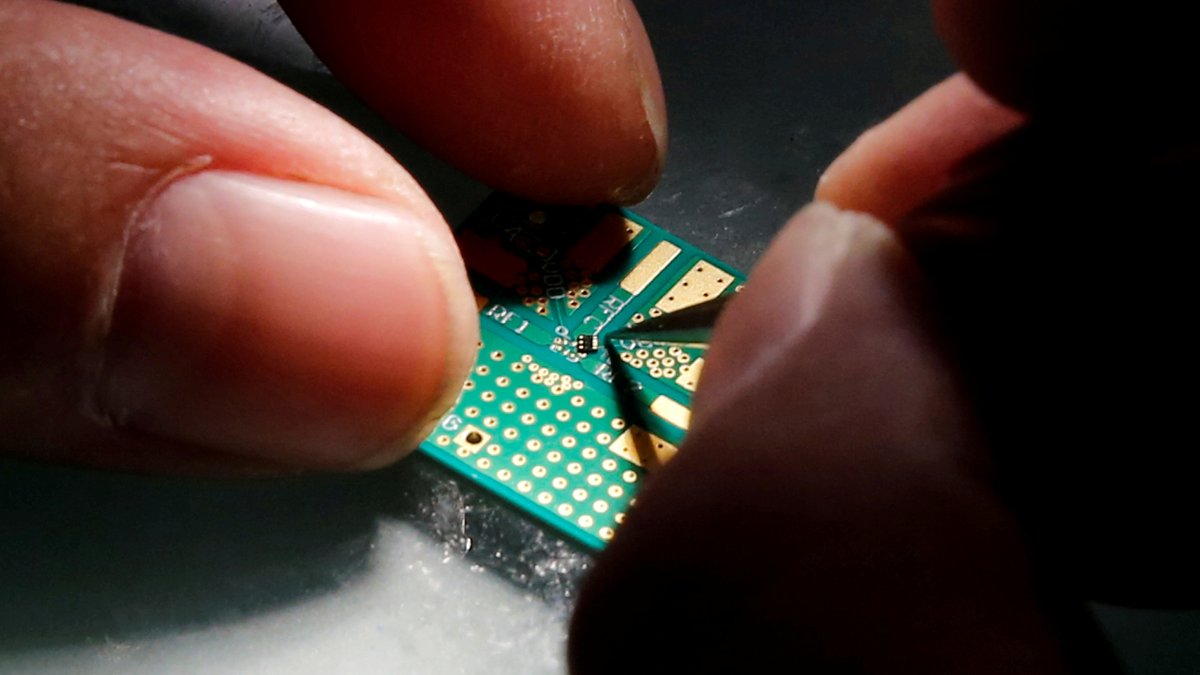

The partnership between India and Micron Technology is a significant milestone in India’s pursuit of becoming a key player in the semiconductor industry. In 2021, the government signed a memorandum of understanding (MoU) with Micron Technology to establish a semiconductor manufacturing plant in India. This state-of-the-art facility is expected to be operational by 2023, contributing to India’s self-reliance in chip manufacturing and reducing its dependence on imports.

- Commercial Opportunities and Innovation Ecosystems:

The collaboration with the United States in the semiconductor sector opens up substantial commercial opportunities for India. As global leaders in chip manufacturing, the partnership facilitates knowledge transfer, technological advancements, and the development of robust innovation ecosystems within the country. By aligning itself with the US, India can position itself more centrally in the global electronics supply chain, fostering economic growth and attracting further investments in the sector.

- Addressing the Semiconductor Crunch:

The global chip shortage, exacerbated by the COVID-19 pandemic, has impacted various industries worldwide. India’s focus on semiconductor manufacturing is a strategic response to this supply chain disruption. By enhancing domestic production capabilities, India aims to mitigate the risk of future chip shortages and create a self-sustaining ecosystem for its technological needs. The partnership with Micron Technology and Applied Materials helps address this semiconductor crunch, strengthening India’s position in meeting its own semiconductor demand and potentially becoming a reliable supplier to global markets.

What are the challenges before India?

- High Investments Required:

Semiconductor and display manufacturing is capital-intensive and involves significant risk and long gestation periods. Setting up semiconductor fabs requires substantial and sustained investments. According to a report by Journals of India, Taiwan and South Korea house “nearly all leading edge (sub

10nm) semiconductor manufacturing capacity”. Of this, 92 per cent are located in Taiwan alone. While 75 per cent of the semiconductor manufacturing capacity is concentrated in East Asia and China. The same report also cites government data to show that India imports 94 per cent of its electronics and 100 per cent of its semiconductors.

- Minimal Fiscal Support:

The fiscal support envisioned currently is relatively modest compared to the scale of investments required for establishing manufacturing capacities in various sub-sectors of the semiconductor industry. The government must consider providing substantial fiscal incentives to attract and retain semiconductor

companies in India.

- Lack of Fabrication Capacities:

India currently lacks advanced semiconductor fabrication facilities. While the Indian Space Research Organisation (ISRO) and the Defence Research and Development Organisation (DRDO) have their respective fab foundries, they primarily cater to their own requirements and are not as sophisticated as the latest global fabs. To develop a thriving semiconductor industry, India needs to invest in cutting-edge fabrication capacities.

- Expensive Fab Setup and Resource Efficiency:

Building a semiconductor fabrication facility requires significant financial resources, a stable power supply, large land areas, clean water sources, and a highly skilled workforce. India needs to overcome these challenges to establish state-of-the-art fabs and ensure resource efficiency in the industry.

Despite the challenges, India’s focus on semiconductor manufacturing offers immense benefits

India’s heavy reliance on chip imports poses economic and strategic vulnerabilities. By bolstering domestic semiconductor manufacturing, India aims to reduce its dependence on foreign suppliers and create a self-reliant ecosystem. The PLI Scheme, coupled with collaborations with leading chip makers like Micron Technology and Applied Materials play a pivotal role in achieving this goal.

The establishment of semiconductor manufacturing plants in India will lead to job creation across various skill levels, from research and development to fabrication and assembly. The partnership with academic

institutions, as discussed during PM Modi’s meeting with Gary E Dickerson, CEO of Applied Materials, can help bridge the skill gap by fostering collaborations and training programs, ultimately creating a highly skilled workforce in the semiconductor industry.

The collaborations with Micron Technology and Applied Materials bring advanced process technology and packaging capabilities to India. This infusion of expertise and cutting-edge technologies will drive innovation and pave the way for the development of indigenous semiconductor solutions. By nurturing domestic talent and fostering research and development, India can position itself as a hub for semiconductor innovation.

The growth of the semiconductor industry in India will have a ripple effect on the broader electronics sector. With a robust semiconductor ecosystem in place, the country can attract more electronics manufacturing investments, leading to the expansion of ancillary industries, job creation, and increased exports of electronic goods.

Semiconductor technology plays a crucial role in critical sectors such as defence, aerospace, telecommunications, and healthcare. By strengthening its semiconductor capabilities, India can enhance its national security and reduce vulnerabilities associated with foreign dependencies. Domestic production of secure and reliable chips will ensure the integrity of critical systems and protect sensitive data.

PM Modi’s US visit and partnerships with chip makers like Micron and Applied Materials boost India’s semiconductor industry and self-reliance.

Prime Minister Narendra Modi’s visit to the United States and the subsequent collaborations with leading chip makers signal a major stride towards bolstering India’s semiconductor industry. The partnerships with Micron Technology and Applied Materials, supported by the PLI Scheme and other government initiatives, lay the foundation for India’s self-reliance in semiconductor manufacturing.

The benefits of these collaborations are multifold, including economic growth, job creation, skill development, technological advancements, and enhanced national security. With sustained efforts, India has the potential to emerge as a global semiconductor manufacturing powerhouse, contributing significantly to its economic and technological aspirations.