Green Hydrogen is making the limelight as many countries have taken up the goal to achieve net zero emissions. In 2022, a total of 131 countries, representing approximately 88% of global greenhouse gas emissions, had declared their commitments to achieving net zero targets. Anthropogenic emissions have already surpassed the base level temperature limit of 1.5 degree Celsius as per the Paris Agreement 2015 framework, and in order to bring the temperature increase under 1.5 degree Celsius achieving net-zero emissions becomes imperative.

Green Hydrogen is recognized for its minimal emissions and higher efficiency as compared to the Internal Combustion Engine. By the conclusion of 2021, nearly 47% of global hydrogen production stems from natural gas, 27% from coal, 22% from oil (as a by-product), with only around 4% derived from electrolysis. Considering that electricity boasted an average global renewable share of about 33% in 2021, it implies that merely about 1% of the global hydrogen output generated is Green.

In 2021, electrolytic hydrogen production from dedicated facilities remained constrained to demonstration projects, totaling a capacity of 0.7 GW. However, the 1.5°C Scenario would necessitate a capacity of 4-5 TW( Terawatts) by 2050, demanding a more accelerated growth rate compared to the historical growth rates observed in solar photovoltaic (PV) and wind energy sectors up to the present.

What Is Green Hydrogen?

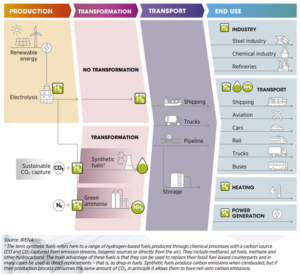

Green Hydrogen also referred to as ‘clean hydrogen’ is the product obtained through process that uses renewable energy resources or other low-carbon methods that have little to no greenhouse gas emissions. In the order to obtain Green Hydrogen water(H2O) is split into Hydrogen(H) and oxygen (O2) by using electrolysis or renewable electricity which can be solar or wind energy.

It is considered to be environment friendly and sustainable as it does not rely on fossil fuels or emit harmful gasses while it is being produced. It has a wide number of utility in various industries such as mobility, aviation, and heavy industries. Electrolytic hydrogen also holds versatile potential applications. It can be utilized in the production of ammonia, serving as a crucial feedstock for fertilizers, which currently constitute the majority of its use.

Additionally, it can be deployed as fuel for emerging sectors such as shipping. Moreover, electrolytic hydrogen can be employed in the synthesis of methanol, synthetic fuels, or even serve as a substitute for coal in iron production as a reducing agent. Upon conversion into these commodities, its energy density is further enhanced, rendering long-distance transportation and long-term storage economically viable.

Challenges Facing Hydrogen’s Potential

Cost

Given long-term average fossil fuel prices of USD 75 per barrel for oil and USD 4-6 per gigajoule for natural gas, producing renewable hydrogen proves to be two to three times costlier than its fossil counterparts. Hydrogen pipelines may incur expenses 10-50% higher. Fuel cells and storage tanks for road transport come with significantly higher costs compared to internal combustion engines.

Currently, synthetic aviation fuels can be three to six times more expensive than traditional jet fuel derived from fossil oil. Moreover, the cost disparity between renewable and fossil-based pathways stands at 50-75% for ammonia, 150% for methanol, and 30-40% for steel.

Electrolyser manufacturing capacity

The growth in electrolysis capacity for dedicated hydrogen production has been notable in recent years, yet the pace is slow, electrolyser manufacturing capacity was merely nearly 11 GW per year in 2022. The capacity needs to be expanded tenfold in order to achieve the temperature targets.

Absence of an Established Hydrogen Market

Hydrogen currently lacks a trading platform, rendering it a non-commodity without a standardized price index. This absence of market dynamics results in limited price transparency and competition, leading to higher costs borne by consumers. Furthermore, the demand for low-carbon hydrogen remains minimal, necessitating comprehensive project integration spanning from supply to infrastructure and eventual end-use.

Scarce Infrastructure for Hydrogen Transport

Globally, the extent of hydrogen pipelines stands at approximately 4,500 kilometers. Leveraging renewable resources from distant areas would entail supplementary investments in transport infrastructure, encompassing pipelines, conversion facilities, liquefaction units, and storage facilities. This amplifies the requisite initial investment significantly.

Water Intensity

Production of green hydrogen is very water intensive and in order to produce 1kg of hydrogen at least eight to ten liters of water is required. This is a challenge for regions that are in midst of acute water crisis and would eventually put a strain on the local resources.

The Way Forward

Accelerating Renewable Energy Deployment

Nations must ramp up efforts to deploy renewable energy sources such as solar and wind power. Implementing policies, making investments, and streamlining regulatory processes are imperative to attract investments and hasten capacity expansion.

Research and Development for Water-Efficient Technologies

It’s crucial to invest in research and development to advance water-efficient hydrogen production technologies. Collaborating with research institutions and international partners can accelerate progress in this area.

Ensuring Stringent Safety Standards

Establishing and enforcing rigorous safety standards and protocols for green hydrogen production, storage, and transportation is essential. Upholding safety measures will instill confidence in the technology.

Infrastructure Development

Constructing essential infrastructure, including pipelines and refueling stations, for green hydrogen production, storage, and distribution is critical for its widespread adoption.

Steps taken by India

At the Glasgow summit, Prime Minister Narendra Modi said, “Today, the world believes that India is the only big economy that has delivered’ on the Paris commitment. We are making every effort with determination.” The Bain & Company report said green hydrogen is critical to helping meet India’s energy security needs while reducing emissions in hard-to-abate sectors on the path to net zero”.

The government initiated the National Green Hydrogen Mission in the beginning of 2022 with the aim of promoting the production and usage of green hydrogen by providing approximately USD 2.3 billion in incentive funding from 2022 to 2030. In a welcome move the government has introduced two busses that run on hydrogen on trial bases that is a part of the bigger masterplan.

India’s green hydrogen production capacity is anticipated to soar, reaching 5 million metric tons per annum. This substantial growth is poised to drastically reduce the country’s dependence on fossil fuel imports. The successful achievement of this mission is forecasted to slash cumulative imports of fossil fuels by an estimated value of INR 1 trillion (equivalent to US$12.03 billion) by the year 2030.

Therefore in order to achieve the targets required to fulfil the net-zero emissions goal there has to be a significant upheaval in the efforts by the global community, and the development of Infrastructure and proper policy measures rest at the heart of the problem. A significant shift in energy consumption matrix will be required to bring about this change. Efforts by the international community are laudable but there are still miles to go.